The Greatest Innovation Since the Assembly Line

By Michael Hugos

The most profound innovation since the assembly line is staring us right in the face. But we don’t see it because we are so busy looking for something else. For most of us the word “innovation” still conjures up images of amazing new gadgets such as technology to turn water into gasoline, black boxes to project moving 3D holograms from our TV sets, and bio-tech breakthroughs that reverse the aging process.

Of course, some of these things will come to pass. But in our fixation on individual gadgets we are missing an innovation that is based on process more than it is on technology. A hundred years ago there was a similar process-based innovation in business that was so profound it became the basis for the economy of the industrial age. That process was the assembly line.

The assembly line and industrial technology are so intertwined in most people’s minds that they do not realize industrial technology had been in widespread use for 50 or 60 years before the assembly line was introduced. It was the process innovation called the assembly line and not new technology that brought our current consumer economy into existence.

The next wave of innovation and productivity will again be based on process and not new technology. A combination of processes that are coming to be collectively known as the “real-time enterprise” will become the basis for our economy in the information age. The real-time enterprise is an organization that employs a set of processes enabled by existing information technology and an organizational structure that allows it to acquire and act on up-to-date information to continually improve existing operations and devise new operations as opportunities arise.

Markets are constantly moving. Product life cycles are measured in months or a few years, no longer in decades. Companies cannot fine-tune their operations to fit some present set of conditions and then expect to simply run those operations unchanged for years and years. That was the old industrial model and that model no longer yields the profits we seek. We need something much more responsive––something that constantly adjusts to changes and opportunities.

The effect of a thousand small adjustments in the operating processes of a company as its markets change is analogous to the effect of compound interest. A real-time organization constantly makes many small adjustments to better respond to its changing environment and in doing so it steadily reduces costs and increases revenues. No one adjustment by itself may be all that significant, but the cumulative effect over time is enormous.

Traditional organizations are now caught in an inexorable squeeze as profit margins on their commodity products and services are relentlessly ratcheted down by the global economy. Soon those companies that cannot earn profits from constant small adjustments will hardly be profitable at all.

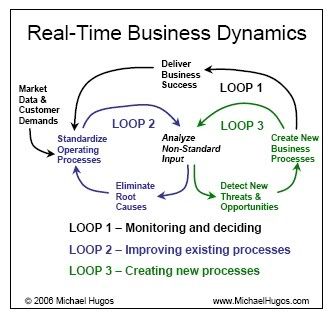

There are three essential processes that combine to bring the real-time enterprise to life (see the diagram below). The main focus of any real-time enterprise is on “non-standard input” or exceptions to the routine. When the company encounters inputs or information from its environment that cannot be handled by its standard operating procedures that means the information either contains errors or it indicates the appearance of something new that has not been seen before and for which there are no standard operating procedures.

The first loop (Loop 1) is for monitoring the environment and deciding what needs to be done. People in Loop 1 are the ones who decide what to do. The people in Loop 1 are responsible for making the decisions about what the company needs to do to achieve the success it desires.

Once a decision has been made, one or both of the other two loops are engaged to act on the decision. People in these processes are the ones who decide how something will be done. One loop (Loop 2) is for improving existing operations. People in this loop find and fix root causes of errors that create non-standard input; that is what delivers efficiency.

The other loop (Loop 3) is for creating new operations. People here design and build new procedures and systems to deal with the appearance of something new; a new threat or a new opportunity. That is what delivers effectiveness. Through the combination of these three loops a real-time organization senses and responds to change in a way that is both efficient and effective.

Loop 1 is a central coordinating body that sets overall enterprise performance goals but it is up to the operating units to figure out how they will act and achieve their goals (Loops 2 & 3). Real-time enterprises push decision-making and authority out to autonomous operating units because that is the only way to be fast enough and responsive enough to consistently capitalize on opportunities and respond to threats as they arise.

[original post: http://blogs.cio.com]

No comments:

Post a Comment